Durability

The durability and flexibility of zinc, this resolutely modern material have been well proven.

Self-protective coating: the secret behind a 100-year lifespan

VMZINC rolled zinc products used in the building industry have a very long lifespan thanks to the capacity of zinc to protect itself when it comes into contact with the main components of the atmosphere.

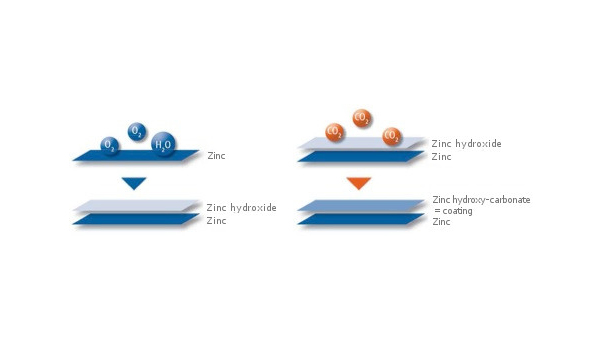

When rolled zinc comes into contact with oxygen, water and carbon dioxide in the atmosphere, a compact, adhesive coating that is very slightly soluble in rainwater forms on its surface. This coating significantly reduces the speed at which atmospheric constituents are distributed to zinc, thus reducing the speed at which the zinc corrodes.

Role of corrosion

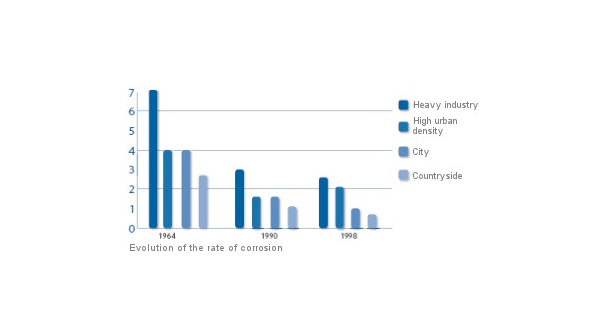

The durability of VMZINC rolled zinc can be affected by certain air pollutants that increase the speed of corrosion. The main pollutant is sulphur dioxide (SO2), produced mainly by industrial production sites, thermal power plants and automobile traffic (which explains why the speed of corrosion of rolled zinc is 4 times faster in industrial environments and twice as fast in urban environments than in rural environments).

Since the 1970s, European legislation and that of other countries has been reinforcing measures to combat this sulphur dioxide pollution, which has led to a considerable decrease in its concentration in the air, and therefore slowed down the speed of corrosion of rolled zinc.

The speed of corrosion of VMZINC rolled zinc is today 1 μm/year on average.

Given that a zinc roof is generally replaced when 75% of its thickness has been corroded and considering initial thickness of 0.65 mm, a simple calculation enables us to understand why rolled zinc lasts a hundred years!

Life span of rolled zinc: case studies

There are numerous examples of rolled zinc roofing installed in various environments over 100 years ago that remain functional today.

To illustrate and explain this fact, samples of old rolled zinc recovered during renovations on very old buildings were analysed using a Scanning Electron Microscope (SEM).

Example: Case study in Liverpool - Roof of the library, sample, image of the sample taken by the SEM.

These analyses highlight the extreme durability of rolled zinc: even after 130 years of exposure, including to particularly aggressive atmospheric components such as sulphur dioxide or chlorine, rolled zinc retains a residual layer of non corroded zinc thick enough to ensure it remains watertight.