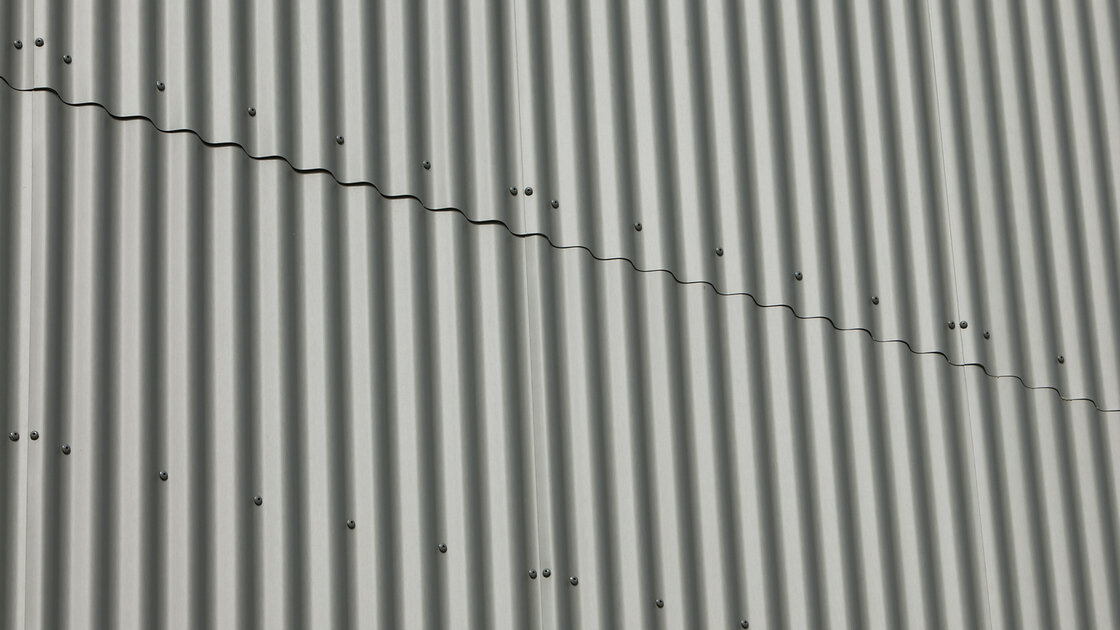

Sine wave profile

- Facade

- Screws

- Visible

- Overlapping

- Sinus profile

- 3 wave depths

- Horizontal or vertical installation

- Fast and easy installation making it a cost effective solution

- Range of components offering a wide variety of all flashing details

- Rhythmic wave aesthetic

General information

It involves installing the Sine wave panels on a metal framework fixed to the supporting structure.

The sine wave panels provide increased freedom of choice and design through the play of light and shadow on the cladding.

Technical data

| Type | 18/76 | 25/115 | 43/180 |

| Wave depth | 18 mm | 25 mm | 43 mm |

| Wave width | 76 mm | 115 mm | 180 mm |

| Useable width | 836 mm | 1,035 mm | 720 mm |

| Length | From 1.8 to 4 m | ||

| Weight (0.8mm) excluding framework | 6.9 kg/m2 | 7.2 kg/m2 | 7.6 kg/m2 |

| Weight (1 mm) excluding framework | 8.7 kg/m2 | 9 kg/m2 (on demand) | 9.5 kg/m2 |

| Radius for natural curving (horizontal installation | 15 m | 30 m | 40 m |

| Finishes | All finishes | Only on Natural zinc, QUARTZ-ZINC, PIGMENTO | All finishes |

Finishes

See all aspects-

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Green

PIGMENTO Green -

PIGMENTO Red

PIGMENTO Red -

QUARTZ-ZINC

QUARTZ-ZINC

Documents and drawings

Please enter your E-mail address. We will send you the download link by mail.

Installation

See all our installation videos-

The VMZINC Sine wave panels are through fixed onto a timber or metal substructure (galvanized steel 1.5mm or Aluminium 2.2mm) spaced at between 800mm and 1200mm depending on project loadings. All fasteners must be stainless steel.

For panels over 3m in length, holes must be slotted to allow for expansion and contraction. A continuous 38 mm ventilated air gap is left clear behind the panels on the entire facade.

Continuous ventilation openings are made at the top and bottom.

The insulation panels must be sufficiently rigid and well anchored to their structure to prevent them from moving and blocking the ventilation space (refer to the insulation manufacturer's specifications).

The cladding supports must be at least 60 mm wide to support the panels correctly.

Any wood treatment products (fungicides, insecticides) must be dry and completely neutral to VMZINC.

Remove of the film

The plastic film must be removed within 2 months of installation. The film should be left on if other trades are working in proximity of the zinc. The film must not be partially removed.