VMZINC and HQE®

The HQE® method is a French sustainable building benchmark that can lead to certification. This benchmark aims to minimise the impact of new and existing buildings on their environment and to optimize the health and comfort of users while ensuring effective, stringent management of the project.

The HQE® method

The HQE® method is a French sustainable building benchmark that can lead to certification.

This benchmark aims to minimise the impact of new and existing buildings on their environment (based on multi-criteria, multi-stage assessment) and to optimize the health and comfort of users while ensuring effective, stringent management of the project.

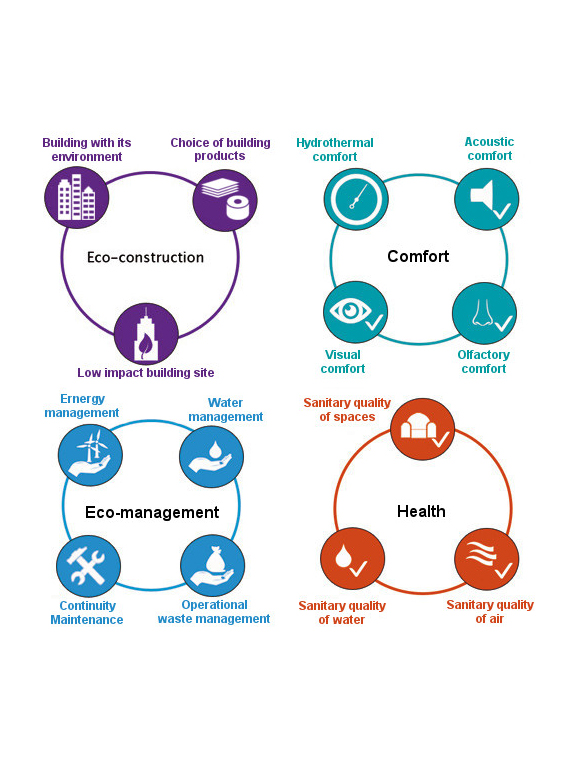

The HQE® method is made up of 14 targets classified in 4 sub-domains: Eco-construction, Comfort, Eco-management & Health.

VMZINC and HQE method

Durable, recyclable, low energy consumption (compared to other rolled metals), maintenance free, FDES (French Environmental and Health Declarations), etc. VMZINC products have many advantages enabling them to contribute to the environmental quality of buildings. When used in building envelopes or, less frequently, as an interior solution, VMZINC solutions contribute more specifically to 4 of the HQE method's targets:

| Sub-domaine | HQE Version 20/01/2012 target | VMZINC advantage | Attainable | Accessible point |

|---|---|---|---|---|

| Eco-construction | Target 1: harmonious blending of the building with its immediate environment | Extent of SRI possibilities according to designers' requirements (SRI AZENGAR > 35) | TP | 2 |

| Target 2: Integrated choice of building products, systems and processes |

| B P TP TP TP B P | 1 5 3 3 3 | |

Target 3: Low impact building site |

| TP | 6 | |

| Eco-management | Target 4: Energy management |

| TP | * * 3 |

* (French Haute Qualité Environnementale method) B = Base, E = Effective, VE = Very Effective

*VMZINC solutions contribute to the thermal performance of the envelope but alone do not enable a number of points to be obtained.

Examples of HQE buildings

Numerous buildings have been designed with the HQE® method and using VMZINC solutions. Two such buildings are presented in this section, one of which was subject to a quantitative environmental assessment using an Environmental Building Quality calculation tool called Elodie.

Toulouse Lardenne Office Building - HQE® and BBC certified

Architect: DR SERAU Architects

Surface aspect: ANTHRA-ZINC

Technique: VMZINC Standing seam

Surface in zinc: 3700 m2 on the roof and facade for 8700 m2 of living space

Luis Ortiz Junior High School in Saint Dizier

Architect: Jean-Philippe Thomas

Surface aspect: QUARTZ-ZINC

Technique: VMZINC Standing seam

Surface in zinc: 1980 m2 on the roof and facade