FAQ

All you want to know about sustainability.

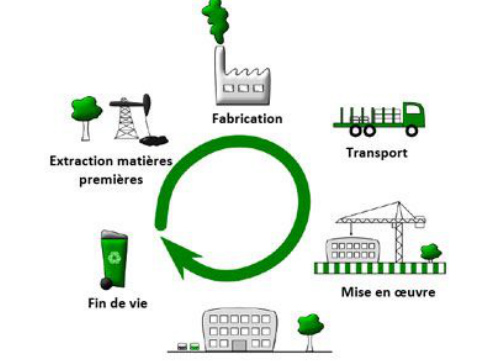

Life Cycle Analysis

What is a Life Cycle Analysis?

A Life Cycle Analysis is a method for assessing the environmental characteristics and potential environmental impacts of a product, process or service:

- By carrying out an exhaustive inventory of incoming flows (energy and matter) and outgoing flows (emissions to air, water, soil and generation of waste) at each stage of the life cycle of a product, process or service,

- By assessing the potential environmental impacts associated with these incoming and outgoing flows,

- By interpreting the results of this inventory and of these potential impacts according to the objectives targeted by the study.

Environmental Product Declarations (EPD)

Do VMZINC solutions have EPD?

Yes, VMZINC solutions have numerous EPD such as FDES, IBU Certifikats and BRE Environmental Profiles.

What does an Environmental Product Declaration that complies with the international ISO 14 025 type III standard consist of?

When a product has an Environmental Product Declaration, it has undergone a Life Cycle Analysis - LCA – in compliance with the international ISO 14040-44 standards and the results of this LCA are communicated in a standardised manner (in compliance with the ISO 14025 type III standard).

What purpose do Environmental Product Declarations serve?

They serve to communicate the environmental impacts associated with the life cycle of a building product in a standardised manner (in compliance with ISO 14025 type III). They are also used in calculation tools to assess the environmental performance of buildings. Thanks to EPD, the contribution of building products to the environmental performance of buildings can be quantified.

Environmental certifications

Do VM BUILDING SOLUTIONS and/or VMZINC products have environmental certifications?

Yes, VM BUILDING SOLUTIONS and VMZINC products have environmental certifications:

- the 3 main French production sites are ISO 14001 certified,

- VMZINC products have Environmental Product Declarations in compliance with the international ISO 14025 Type III standard, such as French Environmental and Health Declarations (FDES), IBU Certifikats and BRE Environmental Profiles.

What are the environmental issues identified and controlled as part of the ISO 14001 certification of VM BUILDING SOLUTIONS production sites?

The main environmental issues concern energy consumption, risks of pollution (water, air, soil), saving water and waste management. However, regarding risks of pollution, the latter are very limited and entirely controlled at the 3 main VM BUILDING SOLUTIONS production sites in France.

What are the examples of actions implemented as part of the ISO 14001 certification to reduce or eliminate environmental risks?

One example is the installation of high performance filtration systems at the exit of the zinc and alloy smelting furnaces' chimney flues, which makes it possible to minimize metal emissions in the air with significantly lower content than regulatory emission thresholds. Another example is the installation of a closed circuit cooling system that enables annual savings of 280,000 m3 of water at Auby.

What does the ISO 14001 environmental certification of production sites consist of?

Being ISO 14001 certified means that environmental risks are identified, measured and reduced or eliminated. In concrete terms, ambitious improvement objectives expressed using measurable environmental indicators are set in multi-annual plans and are then measured, checked and validated by an external auditor and an independent body that awards certification. The environmental progression validated at the VMZINC sites is a reflection of the group's behavioural maturity in terms of environmental management.

Which VM BUILDING SOLUTIONS activities are covered by the scope of its ISO 14001 certification?

All activities relating to smelting, casting, rolling, preweathering, sizing, forming and storage of VMZINC rolled zinc solutions are covered by the scope of the ISO14001 certification. At the Viviez site, activities relating to water treatment and remediation of historic pollution at the site are also covered by the scope of this certification. The remediation project for historic pollution at the Viviez site represents a 35 million euro investment, 1 million cubic metres of treated soil and over 10 years of work.

Traceability of mining resources

Are the principles of sustainable development respected in the mines from which the zinc ore used in VMZINC solutions is extracted?

Yes, the principles of sustainable development are respected in the mines from which the zinc ore used in VMZINC solutions is extracted.

Are the zinc ores used for VMZINC solutions traceable?

Yes, in the case of over 70% of ores used for VMZINC solutions because VM BUILDING SOLUTIONS' main primary zinc supplier, Nyrstar, owns a majority of the mines that supply the zinc ores used to manufacture its primary zinc. Nyrstar publishes a detailed annual sustainable development report providing traceability of the zinc ores used for VMZINC solutions.

Does VM BUILDING SOLUTIONS own and take responsibility for the zinc mines that are the source of the VMZINC solutions it markets?

No, VM BUILDING SOLUTIONS neither owns nor is directly responsible for the zinc mines that are the source of the VMZINC solutions it markets. Neither is the manufacture of primary zinc using zinc ore part of the scope of its responsibilities.

Generally speaking, do the mining companies that extract zinc resources respect the principles of sustainable development?

The vast majority of mining companies extracting zinc resources are members of the International Zinc Association (IZA) and as such have signed the “Sustainable Development” Chart and “Sustainable Commitments” (to which all members of the IZA commit. VM Building Solutions is an active member of the IZA).

How does VM BUILDING SOLUTIONS make sure that the principles of sustainable development are respected in the mines from which the zinc used in VMZINC solutions is extracted?

The sustainable development report published annually by Nyrstar gives VM Building Solutions visibility of the actions put in place to respect the principles of sustainable development.

What are the examples of economic indicators presented in this sustainable development report?

In Nyrstar's sustainable development report, economic objectives are more specifically monitored using 5 indicators including, for example, annual income from external clients or operational costs per site.

What are the examples of environmental indicators presented in this sustainable development report?

In Nyrstar's sustainable development report, environmental objectives are more specifically monitored using 14 indicators relating to environmental incidents recorded, metal emissions in air and water, greenhouse gas emissions, water consumption, energy consumption and waste management.

What are the examples of social indicators, especially relating to human rights, presented in this sustainable development report?

In Nyrstar's sustainable development report, social objectives are more specifically monitored using 4 indicators. For example, we can quote the “age pyramid” and “men/women breakdown” indicators, which enable the eradication of child labour and discrimination in the workplace to be monitored.

Association's (IZA) “Sustainable Development” Chart and “Sustainable Commitments” contain?

The IZA's “Sustainable Development” Chart and “Sustainable Commitments” contain, among others, the following commitments:

- Development of sustainability indicators,

- Development of and communication on the essential contribution of zinc to human health and to eco-systems, as well as on the potential impacts for the environment (assessed based on scientific risk analyses),

- Ensuring effective use of resources to produce and recycle zinc,

- Reduce energy consumption along the whole value chain,

- Control of limited and extensive zinc emissions,

- Production in compliance with international environmental and social standards,

- Incorporate a “life cycle” dimension in production of products.

What does the VM BUILDING SOLUTIONS sustainable supply chart contain in terms of respect for human rights?

In terms of respect for human rights, the VM BUILDING SOLUTIONS sustainable supply chart has its suppliers commit to:

- eradicating child labour,

- eradicating forced or compulsory labour,

- authorising freedom of association and the right to reclamation,

- eradicating discrimination in the workplace,

- treating employees fairly,

- respecting the applicable laws in terms of working time, compensation and remuneration.

What does VM BUILDING SOLUTIONS put in place to incentivise and promote respect for the principles of sustainable development in the mines from which the zinc used in VMZINC solutions is extracted?

- As part of VMZINC sustainable development policy, VM BUILDING SOLUTIONS defined a sustainable supply chart which it asks its main suppliers, including Nyrstar, to sign. By signing this chart, suppliers commit to respecting a certain number of environmental, social and economic principles, including the main principles relating to human rights.

What is contained in Nyrstar's sustainable development report?

- This sustainable development report details Nyrstar's environmental, social and economic objectives and demonstrates, by monitoring measurable indicators from one year to the next, the progress achieved for all these objectives.

Where do the zinc ores used for VMZINC solutions come from?

- The zinc ores used for VMZINC solutions come mainly from 3 geographic regions that can be broken down as follows:

- 33% from North America (USA, Canada)

- 20 % from Europe (Finland)

- 17% from South America (Mexico, Chile and Peru)

- The rest comes from various geographic regions.

Which stage in the manufacture of VMZINC solutions is directly covered by VM BUILDING SOLUTIONS scope of responsibility?

VM BUILDING SOLUTIONS is responsible for the manufacture of alloyed rolled zinc and rolled zinc solutions for building envelopes which are manufactured by smelting the primary zinc and alloys (copper, titanium) that it purchases from suppliers.

Zinc emissions

Does runoff from rolled zinc generate a risk for the environment?

Generally, emissions of zinc in rainwater that has been in contact with rolled zinc constructive systems do not generate a risk for the environment.

Zinc is naturally present in the environment and has always been used by humans for development and growth, making zinc the 3rd most important trace element after iron and magnesium for human beings.

When zinc is released into the environment, a significant quantity reacts with the other components of the environment such as oxides or organic matter (speciation), leaving a small quantity of zinc available for utilisation by living organisms (bio-availability). Generally, in the soil, over 90% of zinc released binds to soil particles and only 10% remains available for utilisation by living organisms; in water, 70% of zinc released binds to sediments (4).

The behaviour of zinc in the environment was modelled and the modelling was incorporated into the environmental risk assessment methods used at European level. In any case, for a given project, regardless of the envelope materials used, it is vital to conduct an environmental impact study if direct evacuation of rainwater into the environment is envisaged.

(4) “Atmospheric corrosion, runoff and environmental effects of zinc-based materials” I.Odnevall et Al. Workshop “Galvanizing of steel stip” Luxembourg February 27-28th, 2002

In Europe, do the levels of zinc in the environment generate a risk for humans and the environment?

The conclusions of this Risk Assessment are that there is no regional risk for humans or the environment and that it is not necessary to reduce the use of products made from zinc or containing zinc used on the European market (fertilisers, pneumatics, paints, building products, etc.) (5).

(5) European Risk Assessment for zinc and zinc compounds – CASE n° 7440-66-6 and EINECS n° 231-175-3

Is zinc a natural element?

Yes, zinc is a natural element in the earth's crust; it is an integral part of our environment. Zinc is naturally present in rocks and soil, as well as in the air, water and the biosphere. Plants, animals and human beings contain and consume zinc.

Minerals and metals are generally obtained from the earth's crust. The average concentration of zinc in the earth's crust is 70 mg/kg (dry weight), with a range of concentrations generally varying between 10 and 300 mg/kg (Malle 1992).

In certain parts of the earth's crust, zinc is present in very high concentrations because of geological and geochemical processes (5-15% or 50,000-15,000 mg/kg). These concentrations of zinc found on the surface of or deep in the earth's crust can be subject to mining.

Is zinc an essential element?

Yes, zinc is an essential element, which means it is absolutely vital for the life of all living organisms.

For humans, zinc is the 3rd most important trace element after iron and magnesium. The OMS recommends a 15 mg daily dose of zinc for men and 12 mg for women.

For humans, zinc contributes to numerous metabolic reactions involved in:

- Growth and cell division,

- Fertility,

- The immune system,

- Taste, smell and appetite,

- Skin, hair and nail renewal,

- Eyesight,

- Etc.

What are the main parameters affecting runoff from rolled zinc?

The main parameters affecting runoff from rolled zinc are:

- Atmospheric sulphur dioxide content (the higher the sulphur dioxide content the greater the runoff).

- Atmospheric chloride content (the higher the chloride content, the greater the runoff).

- The slope of the constructive system (the greater the slope, the smaller the runoff).

- The surface aspect of the rolled zinc (natural runoff > preweathered runoff > coated runoff)

What does the term “Runoff” for a building product mean?

“Runoff” from a building product corresponds to the emission of substances from this product into rainwater that has come in contact with it.

What is the zinc concentration of rainwater having trickled off a rolled zinc roof?

The corrosion and runoff mechanisms of rolled zinc are today well known and documented. This knowledge makes it possible to assess runoff precisely according to a certain number of parameters (atmospheric sulphur dioxide concentration, slope and orientation of the constructive system, surface aspect of the rolled zinc).

Generally speaking, after 5 years of exposure and annual rainfall of between 470 and 790 mm:

- The concentration of zinc in rainwater having trickled off a rolled zinc roof is 4 mg/L (1),

- This concentration is reduced by 30 % in the case of preweathered rolled zinc such as QUARTZ-ZINC® or ANTHRA-ZINC® (1).

- This concentration is reduced by 95% in the case of coated preweathered rolled zinc such as PIGMENTO® (2).

So the concentration of zinc in rainwater having trickled off a rolled zinc roof is generally lower than the drinkability threshold in zinc, set at 5 mg/L in national and international regulations (3) – where this threshold exists, because many regulations relating to the quality of water for human consumption do not set a threshold for zinc, such as the European directive.

(1) “Occurrence and fate of corrosion induced zinc in runoff water from external structures”, Sophia Bertling et al, Science of total environment n°367, February 2006.

(2) Umicore Building Products France internal report

(3) U.S. Environmental Protection Agency (EPA) - National Primary Drinking Water Regulation, French regulation ‘Decree n° 89-3 of 3 January 1989, modified (Appendix I.1) on the limits of quality of water for human consumption” and Danish Regulation